Change management is a quality management tool that will come in handy in your career. As a key part of Good Manufacturing Practices (GMP), change management in pharmacy concerns controlled identification and implementation of required changes in products or manufacturing processes. Management of these changes involves:

- Quality risk evaluation

- Use of experts with applicable expertise and knowledge

- Evaluation of changes after implementation

Change management is applied to the entire lifecycle of a product, meaning it lasts from a product’s creation right until the final moment it is withdrawn from the market. Read on for some more background on change management if you’re interested in quality assurance.

Facilitating Improvements After Quality Assurance Courses

Quality risk management assesses factors that could affect the quality of a pharmaceutical product across its lifecycle. Assessing risks consists of:

- Using information (history, theoretical analysis, etc.) to identify hazards to product quality

- Evaluating risks that result from exposure to the hazards in terms of what could go wrong, severity, and probability

- Linking probability with harm to estimate risk level

Risks can be reduced and/or accepted depending on the appropriate balance chosen between benefits, harm, and resources.

- Risk Reduction is applied when risk exceeds the accepted level, using mitigation processes and checking to see if new risks are introduced by the changes

- Risk Acceptance is chosen when, although not every risk has been mitigated, decision makers feel that risk is at an acceptably low level

How People Factor Into Change Management in Pharmaceutical Sciences

It’s not just the products and their manufacturing that are affected by change. It is important to consider people as well. Change management also includes dealing with developments as they relate to the team.

Succeeding at this requires:

- Structured processes

- Dedicated resources to manage change

- Identification of resistance

- An understanding of why the change is necessary

People are an important component in accepting change and developing products

Change Tools Pharmaceutical Sciences Students Should Know About

Different tools are used by experts in pharmaceutical sciences with applicable knowledge in mitigating change and assessing risks in product or process development. Here are a few that can assist a team in change management:

- Flowcharts

- Check Sheets

- Process Mapping

- Diagrams, especially Fishbone or Cause and Effect diagrams

These tools provide structure by presenting and sorting data for better decision-making.

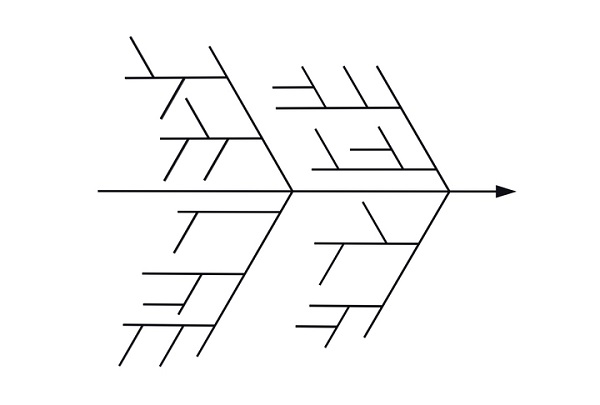

Fishbone Diagrams Show Cause and Effect

Fishbone diagrams, also referred to as Ishikawa or Cause and Effect diagrams, are a popular way to visually display and identify causes behind a particular effect. For example, an issue with a drug could be traced back to specific root causes by drawing and manipulating a fishbone diagram. Potential causes can be categorized and used to design a plan for change.

Fishbone diagrams are a clear visual for sorting out potential causes of a problem

The approach follows this methodology:

1. The problem is identified at the head of the diagram.

2. A straight line representing a backbone runs away from the head.

3. Four or more potential causes of the problem are written out and connected to the spine by lines.

4. Each cause is investigated for contributions to that particular cause.

5. This continues until root causes have been reached.

This and other tools are simple ways to identify what must be changed.

Evaluating Change After Implementation in Pharmaceutical Sciences

As you’ll know from quality assurance courses, risks need to be mitigated with pharmaceutical products. Once a change has been made to a product, new risks could appear, such as:

- Changes to technology

- Threats in cross-contamination

- New facilities

- New equipment

Inspections after changes are crucial to monitor the effects over the lifespan of the product. Materials, packaging, processing steps, and software can all be factors that create new issues. Regulatory practices monitor these products to ensure safety and quality.

Evaluation after changes is important for product quality and safety

Are you interested in getting a Quality Assurance certificate?

Contact AAPS for more information.