Are you considering a career in the Pharmaceutical Quality Control and Quality Assurance industry? With training in this field, you’ll be qualified to work in pharmaceutical laboratories, utilizing many strategies to ensure that manufactured products and treatments are consistently safe for use. By conducting testing, overseeing manufacturing equipment and utilizing your knowledge of regulatory compliance, you can determine whether pharmaceutical products possess their intended characteristics and identity.

While Quality Control (QC) and Quality Assurance (QA) practices have been around for years within pharmaceutical laboratories, technology and other advancements have altered these processes significantly. Not only have labs evolved to improve the efficiency of Quality Assurance and Control, but they’re adapting highly intelligent technologies to ensure accuracy. If you’re interested in becoming a Quality Assurance or Quality Control professional, read on to discover more about how laboratories are evolving to shape these processes.

The Development of Pharmaceutical Quality Assurance and Control Standards

Today, the pharmaceutical industry is guided by a stringent set of standards and regulations, with the goal of ensuring that the products manufactured can be safely consumed and used. However, if you’re enrolled in pharmaceutical school, you may be surprised to learn that drug regulation wasn’t always such a controlled domain.

In 1990, the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICT) was established to manage the quality of pharmaceutical products. Since then, quality assurance and control have evolved to include every step of the product lifecycle, including:

- Planning for New Products

- Creation of Prototypes

- Testing for Drug Stability

- Purchasing of Materials and Containers

- Clinical Trial Production

- Marketing and Product Distribution

Throughout each of these phases, quality assurance and control are implemented as part of current Good Manufacturing Practices (GMP) to keep manufacturers compliant. Given the in-depth nature and importance of quality assurance and control, today, technologies aim to improve the efficiency and accuracy with which they are conducted.

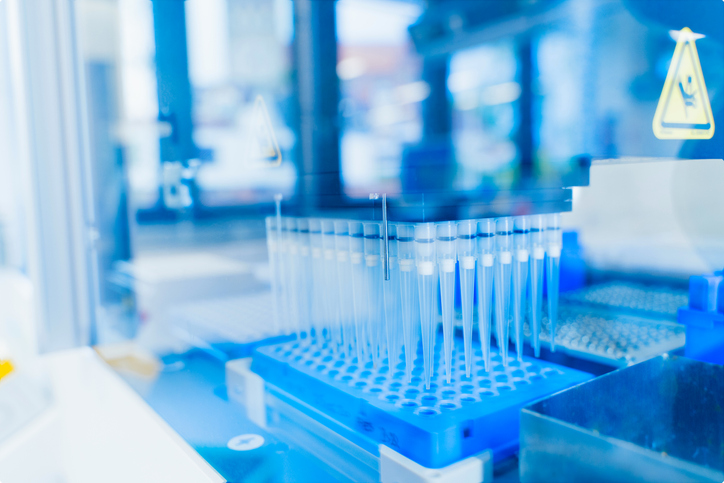

Pharmaceutical quality assurance and control practices keep pharmaceutical products safe for consumption

Emerging Technologies Are Changing the Process

With new and emerging technologies, the ways in which risk is reduced and safety is enhanced have altered over time. Modern technologies have the potential to make pharmaceutical quality assurance and control processes more efficient, more reliable and increasingly industry-aligned. There are three main types of lab evolution, including:

- Digitally enabled labs

- Distributed quality control

- Automated labs

New technologies have affected the operation of labs, and thus, the quality assurance and control performed within them

Within digitally-enabled labs, advanced data analytics is used to prevent any deviations and track trends throughout the development of a product. Not only does this improve productivity by reducing the need for manual documentation, but the data can be used to optimize future scheduling and resource budgeting.

On the other hand, with distributed quality control, real-time release testing is conducted thanks to the use of artificial intelligence. This allows for routine product testing to take place with the use of robots and other AI equipment.

Automated labs rely upon automation technologies to conduct every reproducible task, such as high-volume testing, preparation and sample delivery. This improves efficiency and saves costs in the testing of pharmaceutical products.

Technologies are boosting the efficiency of quality assurance and control

The Future of Pharmaceutical Quality Assurance and Control

Although advanced technologies are changing the scope and methods of conducting QA and QC, implementing these solutions is still far from seamless for pharmaceutical labs. Labs often struggle with making the transformation to using these expensive technologies. This transition can often hamper the quality assurance and control process, and if pharmaceutical labs aren’t able to yield all possible value from the data they obtain, they may not be able to fully enhance the efficiency and accuracy of their QA and QC processes. While these technologies may have a long way to go, the pharmaceutical labs that have already begun to evolve are demonstrating the power of data analytics, artificial intelligence and automation for the quality assurance and control processes.

Are you ready to enroll in pharmaceutical courses in Toronto?

Become a quality assurance expert with a program at AAPS.