Many pharmaceutical companies will develop, test, trial, and manufacture their own drugs and products. However, performing all of these duties is extremely time consuming and requires a lot of resources.

Researchers, laboratory equipment, manufacturing equipment, and quality assurance personnel all come at a premium. Because of these costs, many pharmaceutical and biopharm companies are now outsourcing their manufacturing processes. Companies that provide this outsourcing service are called contract manufacturing organizations.

As a future quality control and assurance professional, here’s what you need to know about contract manufacturing organizations.

Contract Manufacturing Organizations Are Hired to Fulfill Many Duties

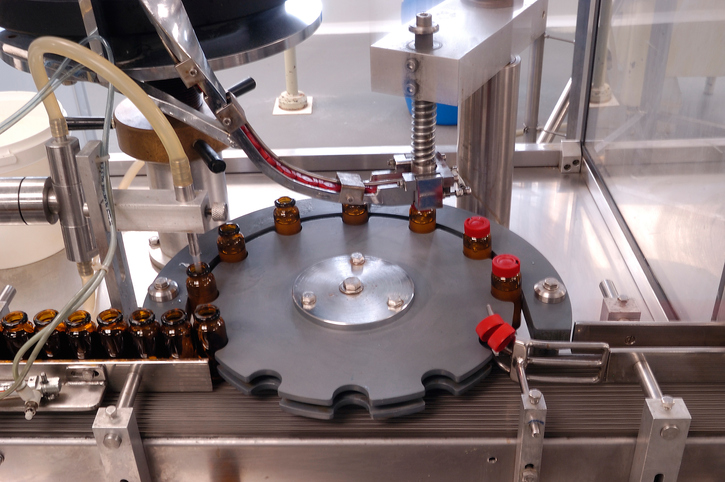

Contract manufacturing organizations (CMOs) are hired by companies in the pharmaceutical industry on a contracted basis to manufacture drugs on their behalf. CMOs provide many different services, from the drug development process through to manufacturing the final product for market. Specifically, these duties could include formulation development, stability studies, producing pre-clinical and Phase 1 clinical trial materials, producing registration batches, and more.

Companies that hire CMOs can choose to just have their end product manufactured for market, or they can decide to involve CMOs in the entire drug development process.

Pharmaceutical Quality Control Students Should Know the Industry Is Growing

From 2013 to 2014 the contract drug manufacturing industry in developed markets such as North America, Europe, and Japan grew by 6 per cent, reaching an astounding $16.5 billion USD in value. In fact, the CMO industry experienced twice the rate of growth that the general global bio/pharmaceutical industry did. This accelerated growth demonstrates how CMOs are gaining in popularity with pharmaceutical companies around the globe.

CMOs now account for about 33 per cent of the entire bio/pharmaceutical industry’s cost of goods. This means that of all global companies, one third of the money spent on producing goods in the industry is spent with CMOs. With CMOs becoming increasingly prevalent, there’s a chance you could find yourself working for one after you graduate from your pharmaceutical quality assurance diploma program.

Pharmaceutical Quality Control Pros Know the Advantages and Disadvantages of CMOs

Outsourcing drug production has its fair share of benefits and drawbacks. When companies hand over the responsibility of manufacturing their product to a CMO they are taking some risks. They no longer have complete control over the cost of producing their product, the quantity and volume produced, or the manufacturing procedures used. From a pharmaceutical quality control standpoint, this could cause concerns when ensuring the production company is adhering to the correct quality assurance standards.

On the other hand, passing off the responsibility to a CMO drastically reduces a company’s costs. Equipment is extremely expensive so companies can greatly reduce start-up expenditures by removing the burden of buying the equipment themselves. In addition, some CMOs specialize in certain areas like biopharmaceuticals or chemical drugs. As a result, companies can hire CMOs specifically suited to manufacture their drug or product. This specialization means the CMO is likely much more efficient than the company could ever be. In addition, because the company’s funds aren’t tied up in the manufacturing process, they can focus on their research and development efforts, potentially exploring new opportunities.

CMOs can manufacture efficiently and help reduce costs

Are you interested in enrolling in quality assurance in pharmaceutical courses?

Contact AAPS today to get started!