Ensuring the quality of pharmaceutical products is an important task. After all, if a manufacturing mistake produces a batch that dissolves slower than normal, patients might accidentally take an extra dose, thinking that they need the added medication to receive the care they need. While these mistakes are rare, it’s still essential for pharmaceutical quality assurance professionals to test the rate at which drugs dissolve.

How do quality assurance experts measure that rate to ensure batch consistency? With the help of dissolution testing.

What is Dissolution Testing?

Before we can define dissolution testing, we’ll need to look at a few key terms such as in vitro, in vivo, and bioavailability.

- In vitro is a test that’s conducted in a culture dish, test tube, or other environment that is outside of a living organism.

- In vivo examines how a drug or substance affects a whole living organism.

- Bioavailability is the rate at which a drug enters the body’s circulation system.

In Latin, in vitro means “in glass.”

These three terms come together during dissolution testing, when pharmaceutical quality assurance professionals measure how quickly a drug releases its active ingredients during lab in vitro tests. That data will help them predict how a drug will release its active ingredients in a patient (in vivo), which in turn helps them determine a drug’s bioavailability.

In short, dissolution testing helps quality assurance professionals determine just how quickly (or slowly) a drug should break down and be absorbed into the body—a key feature of quality assurance.

The Dissolution Process: What Pharmaceutical School Students Need to Keep in Mind

As students begin to complete their Introduction to Pharmaceutical Dissolution Testing Level I and Level II courses, they’ll discover that dissolution occurs in several stages.

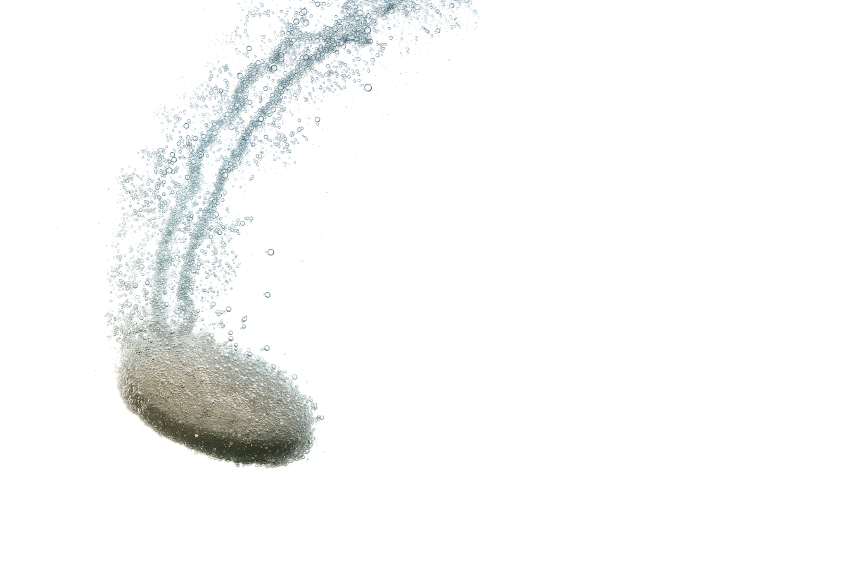

Let’s start with a solid tablet. Once that tablet is swallowed by a hypothetical patient, it’ll begin to break up into smaller particles. This is known as disintegration process, and the rate at which it takes place is the disintegration rate.

Once those particles have completely broken down and are ready to be dissolved, the dissolution process can begin.

A tablet needs to disintegrate before it can dissolve.

How Dissolution Testing is Used for Pharmaceutical Quality Assurance and Beyond

Dissolution testing benefits the pharmaceutical industry in several ways. It advances pharmaceutical sciences by helping manufacturers determine dosage levels when creating a new drug. Dissolution testing can also help ensure that active ingredients break down and are absorbed in a reliable and predictable manner, shelf life doesn’t affect product quality, and transporting a product doesn’t alter how quickly or slowly it takes effect.

However, students will learn that dissolution testing also plays and important role in quality control, since it helps ensure batch consistency. Rather than test batches through in vivo human or animal trials, batches can simply be tested in vitro through dissolution testing—a much safer and cost-effective solution to keeping products safe and consistent.

Do you want to enroll in a top pharmaceutical school?

Discover how AAPS can help you prepare for a rewarding career in quality control!