Foreign objects are defined as materials or components that don’t belong in food items. This includes natural materials (like small rocks or chipped wood), product components (like shells, bones, or feathers), and even processing elements (like plastic, metal, or glass parts from equipment or packaging). Foods containing these foreign objects can present a serious hazard.

This blog post will explore the ways in which foreign objects can be identified, as well as how to prevent contamination in the first place.

Relying on Various Foreign Object Detection Techniques to Ensure Food Quality and Safety

An important step in ensuring top quality is to study the food item carefully and anticipate the common foreign objects typically associated with it. Examples of some common foreign object detection techniques include the following:

- Manual or automated visual inspection

- Thorough washing procedures

- Filtration methods (separating solids from liquids, as well as different sized objects)

- Metal detection/use of magnets (removing metal dust or metallic residue)

Students in food quality training might be interested in learning more about these common foreign object detection methods. Using them more frequently decreases the risk of food contamination—ultimately providing a safer eating experience for consumers. It should be noted that these methods also come with their own set of advantages. For example, metal detectors can help indicate equipment failure in addition to identifying metal fragments in food items. This is crucial as it can prevent food processing interruptions and, in more serious cases, product recalls.

Metal detectors are valuable in identifying foreign objects created by metal equipment

Using Technology Can Help Improve Food Quality Assurance Efforts

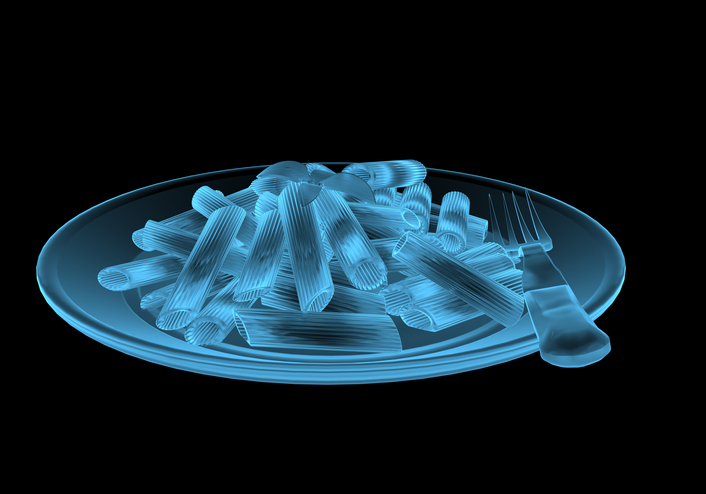

Industry professionals also rely on advanced technology to detect foreign objects in food items. For instance, X-ray inspection is a popular method for identifying foreign objects in food products—particularly as it does so through non-destructive means. X-ray inspection provides an insight into the product’s internal features, easily revealing any defects or contamination without inflicting damage to the product itself. This ability makes it a particularly useful detection tool for various food items, ideal for in-line production quality control.

X-ray inspection can help reveal hidden foreign objects found in food items

The Importance of Foreign Object Detection Explained for Students Interested in Food Quality and Safety

Despite all of these efforts, food contamination can still occur and foreign objects can still be detected even past the packaging stage. This can cause numerous negative repercussions, including the development of a bad reputation, monetary loss, and even significant harm to the end consumer. In this way, food quality assurance becomes absolutely essential in food production. Food quality assurance is all about designing procedures and systems to prevent issues from happening again.

Studying food quality and safety can give you the skills to better prevent food contamination

Having a background in food technology, safety, and quality can be a big help—enabling you to work more efficiently. Understanding food sanitation can play a key role in reducing and preventing food contamination, which will ultimately ensure the safety of various consumers.

Are you interested in learning more about food quality assurance and quality control?

Contact AAPS for more information!